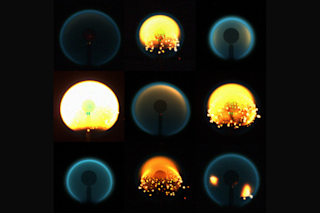

Roy Plunkett was only 27 years old and had been working as a chemist at the Jackson Laboratory at E. I. du Pont de Nemours and Company for just two years when, in the spring of 1938, he made a discovery that brought him lasting fame. He had been trying to invent a new type of Freon, a class of compounds that in the 1930s were proving to be immensely useful as the principal gases in refrigerators and air conditioners. Today we call them chlorofluorocarbons, or cfcs, and know them to be a major culprit in depleting the atmosphere’s ozone layer, but back then they were miracle substances--safe, nonflammable substitutes for toxic and even explosive refrigerants. On an April morning 58 years ago, the young chemist could not have suspected that he was about to discover a material with such strange and unexpected properties that they had hardly even been dreamed of, a material that would eventually become an indispensable part of everything from space capsules to heart valves to frying pans--and one that had absolutely nothing to do with refrigeration. Roy Plunkett was about to discover Teflon. The importance of Plunkett’s story, however, lies not so much in the triumph of invention and commercialization as in what it suggests about the nature of invention itself. Invention is often thought of as systematic problem solving, the kind that supposedly goes on at the well-manicured campuses of corporate research laboratories. In fact, many important inventions arose, and continue to arise, from the creative use of an accident or mistake. This is a unique and somewhat neglected form of creativity, every bit as ingenious and awesome as the more deliberate sort. Much of the act of invention is shrouded in mystery, to be sure. Even when people set out to act purposefully and rationally, they wind up doing things they did not intend. In principle, the accident or the unexpected obstacle that gives rise to a creative invention is not all that different from the unexpected traffic jam that forces us to drive through a new and interesting neighborhood, the pesky weed that turns out to enhance our garden’s variety, or the empty shelf at the supermarket that spurs us to improvise a new recipe. But in practice, events like Plunkett’s are far fewer, and we cannot help asking ourselves: What makes it possible to turn the unlooked-for chance into novel fortune? Not surprisingly, we find a subtle interplay of individual and surroundings: a mind supple enough to turn a screwup into a creative opportunity, and an environment that makes such creativity possible. By the time plunkett started working at Du Pont, the most widely used form of Freon was tetrafluorodichloroethane, also known as refrigerant 114. This was manufactured by a joint Du Pont- General Motors company called Kinetic Chemicals, which supplied it exclusively to the Frigidaire division of gm. Despite the Du Pont-gm link, the chemists at the Jackson Laboratory were responding to the requests of other refrigerator manufacturers for an equally effective refrigerant that could be sold more widely. Plunkett and his colleagues were thus attempting to manufacture a Freon variant that would get around Frigidaire’s patent control of refrigerant 114. Plunkett hypothesized (correctly) that he could start with a compound called tetrafluoroethylene, or tfe, and cause it to react with hydrochloric acid to yield the desired alternative. To test this idea, he decided to make a large quantity of tfe, hitherto a rare and little studied compound. Following suggestions in the chemical literature, Plunkett set up an apparatus to make a hundred pounds of the gas. When asked later Why a hundred pounds? Plunkett replied that he needed a good bit of the gas not only to test for refrigerant properties but also to conduct toxicological tests on animals, and a hundred pounds just seemed like a round number. Because making this much tfe was a complex operation, Plunkett decided to get it out of the way first. A hundred pounds was a lot of tfe, and to store it he needed to round up all the storage canisters he could get his hands on. The most convenient ones to obtain were metal cans, similar to the cans now used for hair sprays, insect poison, and other products in which cfcs serve as a propellant. He set his canisters on top of dry ice so that the tfe inside would liquefy and the pressure inside the cans would be kept low. Precisely these steps set the stage for Plunkett’s surprising discovery. On the morning of April 6, Plunkett and his assistant, Jack Rebok, set up the apparatus for inducing their gas to react with hydrochloric acid. They put a cylinder of tfe on a scale, opened a valve to release the pressure, and allowed the vapor to enter a heated reaction chamber. Then they released a stream of hydrochloric acid into the chamber. The two scientists had run this process so many times in the weeks before that they probably felt they could do it in their sleep, but on this day something went wrong. Once they had put the apparatus together and opened the proper valves, Rebok reported that nothing was coming out of the tfe cylinder. The heft of the cylinder told the men it wasn’t empty, and the scale confirmed that it should contain most of the original gas, but even with the valve opened completely, nothing at all came out. They stuck a wire through the valve to unclog it, but still nothing happened. Exasperated but mystified, Plunkett and Rebok then took off the valve and turned the cylinder upside down and shook it. Small flecks of white powder came drifting out. Plunkett’s first reaction was frustration and disgust, for he instantly surmised what had happened: the tfe in the cylinder had polymerized. In hindsight, this conclusion was pretty surprising. As Plunkett himself later recalled, the general wisdom was that a chlorinated or fluorinated ethylene couldn’t polymerize. Like the proverbial bumblebee that flew because it didn’t know it was aerodynamically incapable of flight, the tfe didn’t know it couldn’t polymerize and went right ahead and did so. Rebok, a high school educated laboratory technician, exclaimed, What the hell is going on, Doc? Worried that they may have lost much of their valuable tfe to this pesky, unexpected reaction, Plunkett and Rebok cut open several of the storage canisters and discovered more than a little bit of white powder: the tfe actually lined the sides of the cylinders with a slick white coating. Curious, Plunkett performed some basic chemical tests but was frustrated: the powder wouldn’t react with any of the basic reagents at hand. He confirmed that the material indeed contained fluorine, but he could hardly determine anything else at that point, so intractable was the substance. As Plunkett later observed, I didn’t know anything about polymer chemistry itself. How, then, did he conclude so swiftly that morning in April that the tfe had polymerized--that its relatively small, simple molecules had combined into long, repetitive chains (and even elaborate webs and tangles) to form giant molecules--transforming the substance itself in the process from a gas to a solid? How is it that his mind was prepared to interpret this chance result? Despite his inexperience with the chemistry of polymers, Plunkett was a well-informed, up-to-date organic chemist, familiar with a range of organic reactions. He knew how simple organic molecules, or monomers, could string themselves together into giant chains. As important, he had also been trained to keep his eyes open to the products of his experiments, whatever they might be--especially when they were not expected. The company in which he worked, moreover, had already established a reputation for nurturing research and discovery. Plunkett was well aware that, at Du Pont, he was surrounded by the best polymer chemists in the world. These were the same people who at that time were putting the finishing touches on the greatest triumph of synthetic polymer chemistry to date: nylon. If Teflon was the prototypical accidental invention of the twentieth century, then nylon was its opposite: a designer material, the product of a clearly directed, hardheaded scientific research campaign. And the emergence of the two different materials from the laboratories of the same company within months of each other underscores the peril of trying to reduce technological creativity to a formula. In an important way, the deliberation that led to nylon paved the way for the accident that gave rise to Teflon. A decade before Plunkett gazed in puzzlement at his white-coated canisters, Charles M. A. Stine, the director of Du Pont’s Chemical Department, had initiated a program of basic chemical research aimed merely at discovering new scientific facts. A key focus for this work was polymerization, and to guide research in this area Stine hired a young Harvard instructor by the name of Wallace H. Carothers and installed him in a new laboratory at the Du Pont research center on the outskirts of Wilmington, Delaware. When Carothers started at Du Pont, chemists were just beginning to accept the idea of polymerization. For years they believed that molecules, because they were by definition building blocks of materials, could not themselves take on elaborate proportions. The tendency of many important organic materials, such as proteins or cellulose, to behave as macromolecules was commonly ascribed to another phenomenon entirely-- their tendency to form colloids, or clusters, when put in solution. In the 1920s, however, the German chemist Hermann Staudinger exposed the flaws in the colloid theory. Other German chemists began to produce potentially valuable polymers in the laboratory--materials such as polystyrene and polyvinyl chloride, familiar to us as common plastics. Small wonder, then, that Du Pont wished to understand and exploit this new kind of chemistry. Within just a few years, Carothers and his team had established important new theoretical and practical foundations for polymer chemistry, and they quickly exploited this knowledge for potential new products. Among the first polymer reactions that the Du Pont team explored was a fairly simple one that combined esters--compounds made by causing an acid and an alcohol to react and removing the water by-product--into long chains called polyesters. As early as 1930, Carothers’s chief associate, Julian Hill, demonstrated how this work might yield new synthetic fibers, a major goal of Du Pont’s polymer research from the first. When he dipped a glass rod into a beaker of experimental polyester and drew it out, the material emerged like a long strand of taffy. Once cooled and pulled, the strand stretched to four times its original length and then suddenly would stretch no further. Years later, Hill spoke with amazement of the sensation of virtually feeling the molecules lock into place. This cold-drawing was the key to making strong synthetic fibers. Polyesters were easy enough to make, but concocting one that had a high melting point (early polyesters melted in boiling water) took several decades of further research. In the meantime, the Du Pont chemists turned their attention to polyamides, compounds made from the reaction of an ester with ammonia. Polyamides, they reasoned, should polymerize much as the esters did, and at the same time should more closely approach the desired toughness of silk. They were correct: by May 1934 Carothers’s lab produced the first version of what was to become known as nylon. Over the next nine months, the Du Pont team continued its systematic attack, surveying more than 80 different polyamides and narrowing the field to five promising commercial possibilities. Eventually, polymer 6-6 was deemed the best, despite a somewhat disappointingly low melting point of 505 degrees Fahrenheit. Since the properties of the new fiber were suited to making finer women’s hosiery, a development team went to work solving the inevitable host of problems, from manufacturing the polymer in high quantity to finishing, spinning, dying, and working the fiber itself. Finally, in autumn 1938 the company announced, with enormous public fanfare on the grounds of the soon-to-be-opened World’s Fair at Flushing Meadow in New York City, the first man-made organic textile fiber. Nylon, made solely from coal, water, and air, was as strong as steel, as fine as the spider’s web. Most significantly, perhaps, the material was hailed by the press as a stirring confirmation of Du Pont’s new advertising promise: Better Things for Better Living Through Chemistry. There could have been no grander testimony to the power of systematic scientific research to transform life through invention. Tragically, a year and a half before the unveiling of nylon and just two days past his forty-first birthday, the moody Carothers took cyanide in a Philadelphia hotel room. Although he had suffered from severe bouts of depression off and on for years, his suicide shocked his colleagues. Carothers was at the peak of his scientific influence and technical creativity, and his untimely end added mystique to his reputation of genius. That reputation, however, was well deserved. Nylon is an example of outstanding scientific and inventive creativity. Back in the late 1920s, when Carothers was just beginning his research for Du Pont, chemists were still debating whether polymers even existed. By the time he died, chemists held dogmatically to the opposite belief--that these giant molecules made up most of the entire organic world around us. The nylon that he never saw to market stood for the next 50 years as the single most spectacular instance of chemical invention, of the capacity of scientifically trained chemists to refashion the natural world as they wished, simply from coal, water, and air. The high standard of research that Carothers maintained is perhaps best exemplified by a brilliant young chemist he recruited to help put nylon on a firm scientific footing. Paul Flory, by a remarkable coincidence, had been Roy Plunkett’s roommate at tiny Manchester College in Indiana and had preceded Plunkett to both Ohio State and Du Pont. But the similarities end there, for while Plunkett was to content himself managing problems in chemical production at Du Pont his entire career, Flory went on to become one of America’s most accomplished research chemists, receiving the Nobel Prize in 1974 for his work in polymer chemistry. Carothers apparently recognized this promise when he put Flory to work analyzing polyamide reactions in 1934. To some degree, the contrasting reputations of these two scientists underscore how the prejudices and styles of science and technology were evolving in the middle of the twentieth century. Whereas Plunkett proceeded by luck and serendipity, Flory took the high road of theoretical and systematic methodology, upon which corporate research laboratories increasingly sought to rely. With his stature and influence in the scientific community, Flory embodied the growing prestige attached to theoretical science. Roy Plunkett’s relative obscurity showed how far technological creativity had come to be seen as an almost purely corporate, communal activity. All of this, of course, lay in the future as Plunkett struggled to make sense of his laboratory failure in early April 1938. He thought the tfe had polymerized, but how could he test it? When heated, the tfe softened like a plastic, melted, and eventually went up in smoke. When he tried to dissolve it, it wouldn’t mix with any liquid available in the laboratory. Intrigued, he sent some of the flaky material to Du Pont’s Central Research Department. They made a bigger batch of the stuff and found that with some difficulty they could mold it. One of the first things they noticed was that it was extremely slick. A few more tests revealed that it resisted electric currents as well as it did most chemical action. In short, it was the slickest, most inert material they had ever seen. Although this seemed promising in a theoretical sort of way, Plunkett recalled, this stuff was going to cost so much that nobody was ever going to buy it. Such thoughts, though, did not deter Plunkett from spending a few more months investigating what had happened inside his cylinders of tfe. Eventually he succeeded in figuring out what combination of temperature, pressure, and other conditions had occurred by chance inside the cylinders, and how to reproduce it. Once he was able to describe the polymerization reaction that yielded polytetrafluoroethylene, or ptfe, he filed a patent on Du Pont’s behalf. Still, the expensive, unwieldy material might have been quickly shelved had it not been for the outbreak of World War II and the crash project to build an atomic bomb. Producing the radioactive isotope of uranium that served as fuel for the bomb required handling enormous quantities of uranium hexafluoride, one of the most caustic and toxic substances known. Scientists needed something that would resist its corrosive action, and Plunkett’s ptfe (the name Teflon was not coined until 1944) fit the bill. Taking advantage of ptfe’s transparency to radar and its electrical resistivity, engineers also molded it into nose cones for proximity bombs. These wartime applications convinced Du Pont and others that the material’s special properties warranted the effort and expense of additional research to lower its cost and improve methods of production. It took more than a decade after the war ended, but eventually Teflon was made cheap enough for use in consumer products. Roy Plunkett’s own involvement in developing the material he invented did not survive the war years. After all, he was not a polymer chemist, and so he was perfectly happy to take on other Du Pont assignments, although as the company continued to file patents around the world on his discovery, he was repeatedly called on to sign the applications. Nobody doubts that nylon was a great feat of scientific creativity. But what of Teflon? Do we just chalk it up as a lucky fluke, falling outside the realm of creative technology? Or is it the fruit of another kind of creativity, one that, although perhaps harder to recognize at first glance, is as fundamental a part of the story of invention as the systematic campaigns that we are told about so readily? Louis pasteur, one of the greatest of all serendipitous discoverers, said: Fortune favors the prepared mind. Roy Plunkett had no hesitation in thinking polymer as soon as he opened his ruined gas canisters that April morning. It wasn’t because he was looking for polymers, or even because he was particularly familiar with them. But he was a well-trained chemist working in an environment in which the importance of polymerization was apparent to every thinking researcher. His mind was prepared, as is usually the case in such instances, by his past and his present, working together harmoniously and creatively. Creative invention almost always hinges on the act of creative observation. Plunkett allowed himself to see what he wasn’t looking for. In the case of Charles Goodyear, who invented the process of vulcanization in 1839, creative observation meant allowing himself to take his research in an unanticipated direction. His story is among the most familiar in the canon of technology’s great accidents. For more than a decade, Goodyear, a Connecticut hardware salesman, had been experimenting with ways of making rubber easier to work and more impervious to heat or cold. One day, while working in the kitchen of a boardinghouse in Woburn, Massachusetts, he spilled a mixture of rubber, sulfur, and white lead onto the hot stove and charred it. When he picked it up he saw that it had hardened but was still quite usable. Although it took a bit more experimentation to determine how to fashion this accident into a practical vulcanization process (the combination of heat and sulfur was crucial; the white lead turned out to be extraneous), the accident was always seen as the core of his invention. In other cases the element of surprise seems more profound and the response to novelty more ingenious. In 1856, William Henry Perkin was an 18-year-old student working in the new laboratory of August Wilhelm von Hofmann at London’s Royal College of Chemistry. Hofmann put his young student to work on an ambitious project to synthesize a chemical resembling the antimalarial drug quinine from the coal-tar distillate allyltoluidine, which seemed chemically similar. Perkin tackled the problem with the enthusiasm and naïveté of a young man with only a vague sense of the complexities of organic synthesis. Predictably, he came up with nothing but a worthless rust-colored mud. He substituted aniline, a somewhat simpler coal-tar distillate, for the allyltoluidine, but the only real change seemed to be in the color of the mud. It now appeared almost black. Perkin boiled the black sludge to yield a crystalline precipitate, which, when dissolved in water, turned into a brilliant purple. This gave him the idea to try to dye a piece of cloth. The resulting hue was so striking he dubbed it mauve, from the French for the flowers of the mallow. This was the beginning of the synthetic dye industry. Why Perkin should be thinking dyes when he had failed to make a drug is by no means obvious. Of course, by the 1850s, the textile industry in England had been vastly expanding, and the great personal fortunes being made from it were not lost on the young Perkin. But to explain his insight purely in economic terms is to give the imagination short shrift. By thinking dyes, he turned an accident into a surpassingly original creation. Nor was Perkin a one-shot wonder. In subsequent years, he proved himself to be a chemist of brilliance and intuition. The history of invention has plenty of such creative accidents. In the fall of 1895, Wilhelm Röntgen, a professor of physics in Würzburg, Germany, was working in his laboratory with a Crookes tube--an early version of an electronic vacuum tube. He wanted to know how easily the glow from a Crookes tube could be masked, so he covered it with dark paper, powered it up, and darkened the lab. The paper blocked the tube’s glow, all right, but across the room Röntgen noticed that a screen treated with barium platinocyanide, which was used to demonstrate fluorescence, was now glowing, and when he moved the screen closer to the tube, the glow brightened. All visible light from the tube was clearly blocked by the paper, and further experiments showed that any energetic particles (shortly to be named electrons) were also blocked from the screen. The glow was, Röntgen concluded, being caused by a new kind of invisible light that could pass through all but the densest materials. In testimony to the aura of mystery that seemed to surround the phenomenon, he called the discharge X- rays. In a matter of weeks, X-rays were used by German physicians to examine a bullet wound--perhaps one of the fastest translations into practice of any scientific discovery. The twentieth century saw its own share of creative accidents, à la Teflon. The idea for radar came from the observation that radio waves accidentally bounced off passing ships. The microwave oven occurred to an experimenter when a chocolate bar melted in his pocket while he was working with a magnetron. Perhaps the most famous of all was Alexander Fleming’s discovery of penicillin from a stray mold on the surface of a bacterial culture. Whenever we attempt to do something and we fail, we end up doing something else. As simplistic as this statement may seem, it is the first principle of the creative accident. We may ask ourselves why we have failed to do what we intended, and this is a perfectly reasonable, indeed expected, thing to do. But the creative accident provokes a different question: What have we done? Answering that question in a novel, unexpected way is the essential creative act. It is not luck but creative insight of the highest order.

The Accidental Inventor

Christopher Columbus of chemists, set boldly forth to discover a new technology of refrigeration. Luckily, he screwed up and invented Teflon instead. The knack for serendipity may turn out to be the investor's most important talent.

More on Discover

Stay Curious

SubscribeTo The Magazine

Save up to 40% off the cover price when you subscribe to Discover magazine.

Subscribe