Pull apart any electrical device and you will find a riot of right angles, straight lines and flat, uncompromising silicon wafers. John Rogers is changing that. The 45-year-old materials scientist has spent more than 15 years developing electronics that can bend and stretch without breaking. His devices, from surgical sutures that monitor skin temperature to biodegradable sensors that dissolve when their useful life is done, share a unifying quality: They can slip seamlessly into the soft, moist, moving conditions of the living world.

Other scientists construct flexible electronics from innately bendy materials such as graphene, a lattice of pure carbon only one atom thick. From his lab at the University of Illinois at Urbana-Champaign, Rogers has bucked the trend, building most of his devices from silicon, a normally rigid material — but one that, due to widespread use and desirable attributes such as outstanding thermal conductivity, has a track record of efficiency and low cost.

Rogers’ team has tapped silicon’s rep for reliability by tricking it into a more malleable form. Rather than making transistors from conventional silicon wafers, they slice the material into sheets several times thinner than a human hair. “At this scale,” Rogers says, “something that would otherwise be brittle is completely floppy.”

Riding this approach, Rogers has filed dozens of patents and launched five companies to get his products off the ground. His Cambridge, Mass., company MC10 is developing sensors that can fit the contours of the brain or heart to monitor for early signs of epileptic seizures or heart arrhythmias. North Carolina-based Semprius is making ultra-efficient solar cells as thin as a pencil tip and flexible enough to roll into a tube or print on plastic or cloth.

With all his devices, including the five spotlighted here, Rogers’ goal is to make a lasting impact. “If we were successful beyond our wildest dreams,” he says, it’s important that people would care.

Bug's Eye View

Anyone who has tried and failed to swat a fly can appreciate the benefits of its wide field of view and keen ability to detect movement. The advantage derives from insects’ compound eyes, which scoop up visual information through hundreds or thousands of visual receptors, called ommatidia, covering the eye’s curved surface. The more receptors, the more information the brain can assemble, and therefore, the more acute the insect’s vision.

Building on earlier work modeling a camera on the shape of a human eye, Rogers and his team recently unveiled a camera inspired by an insect’s compound eye. Instead of making a single curved lens to focus light onto a flat surface, they built a camera packed with tiny lenses, each connected to an individual photodetector. “The uniqueness of this design,” Rogers says, “is that it sees in all directions at once.”

The camera also renders both close-up and faraway objects in perfect focus. And because each lens needs to process only a narrow field of view — and therefore a small packet of data — the camera responds quickly to moving objects, just like insects do. “If you’re interested in a surveillance system, those properties are important,” Rogers says. Compound cameras could also be useful in medical procedures, such as endoscopy, that require a close-up view inside body cavities.

Rogers’ current camera has only modest resolution, akin to that of a fire ant or bark beetle, insects with relatively few ommatidia. He plans to scale up to higher resolutions, mimicking the ocular prowess of a praying mantis or a dragonfly. And eventually, he hopes to achieve resolutions “that exceed anything that has ever existed in biology.”

Fits Like a Glove

Imagine that one day years from now, a peculiar pattern of electrical activity courses through your heart, causing it to beat erratically. But before you develop full-blown arrhythmia, which can be life-threatening, a network of hundreds of sensors steps in. Conforming to the shape of your heart, the network delivers its own set of electrical pulses, resetting the normal rhythm. And you barely feel a thing.

Rogers has moved toward this futuristic vision by creating sensor arrays that can precisely mold to the shape of body organs. Heart sensors made of stretchy, lightweight material and embedded with electronics envelop the heart like a thin sock, providing real-time measurements of cardiac activity.

The goal, Rogers says, is to detect early signs of arrhythmia and deliver coordinated voltages across the entire organ, rather than delivering massive, painful shocks at a few points, as current defibrillators do. His collaborators at Washington University in St. Louis have tested the device, which he calls an “artificial pericardium,” on rabbits and on human hearts removed from transplant recipients, and trials in live patients could be close.

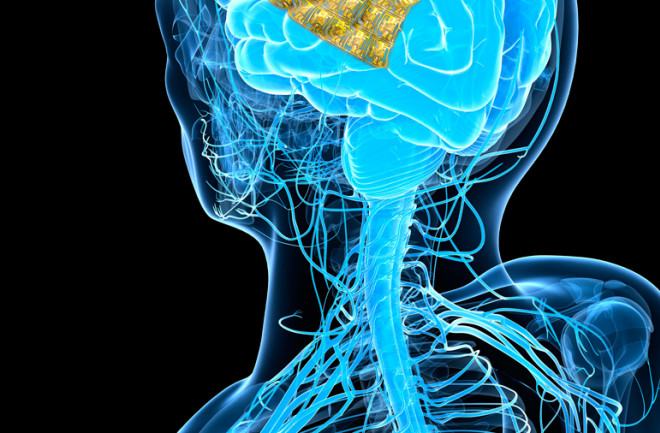

Another of Rogers’ devices is designed to detect early signs of epileptic seizures. But unlike other brain implants, which either sit on the scalp or have to be jabbed into brain tissue, this one sits on the surface of the brain. And while modern electrodes can scan the brain either over a large area or in great detail, Rogers’ device can do both.

Developed with colleagues at the Penn Epilepsy Center, the device measures brain activity using an array of 360 electrodes encapsulated in silk. When the silk dissolves, the array molds to the organ’s surface like shrink-wrap, even folding into the brain’s otherwise-inaccessible nooks and crannies.

In a recent test using a cat as a test subject, Rogers’ team showed that the sensors, connected to computers via a thin cable, could identify specific neural signals that portend a seizure. He plans to develop a wireless system and scale up the sensors to human size; after that, he says, surgeons could use them to monitor seizures in the brains of epileptic patients, helping guide surgical decisions. Rogers also envisions implants that could detect signs of seizure and then stimulate local neurons to prevent electrical buildup, perhaps averting seizures entirely.

Just Add Water

Normally, electronic devices destined for damp environs are built to withstand moisture. Rogers and his crew have designed electronics that do the opposite, dissolving without a trace over a period of minutes, hours, days or weeks — and potentially even years.

Such “transient” electronics, as Rogers calls them, could monitor and prevent infection at surgical sites, then resorb into the body on a predetermined schedule. They could also be used as environmental sensors, monitoring an oil spill or chemical contamination site, for instance, and then dissolving once the disaster is cleaned up, saving recovery teams the ordeal of collection.

Transient electronics would also be valuable to the military, enabling devices carrying them to collect sensitive information, then disappear into thin air (or water, as the case may be).

Not only do Rogers’ transient devices dissolve into the environment, they are also harmless when they do. In fact, Rogers says, most “ingredients” in his devices are listed on a bottle of daily vitamins. During a talk at a recent electrical engineering conference, a colleague bet Rogers that he wouldn’t dare pop one of the transient devices into his mouth and swallow it on stage; Rogers won the bet.

To create the technology, Rogers’ team started with a film of purified silk, which is bendable and extremely soluble in water. Rather than using traditional aluminum or copper to make electrodes that serve as sensors, the team used magnesium, a nontoxic metal that’s highly conductive and dissolves in water. And instead of using conventional silicon wafers for transistors and diodes, they used silicon layers only 50 nanometers thick, enabling the components to dissolve in a couple of weeks.

Finally, the team coated the entire device in magnesium oxide, another nontoxic compound — often given as an antacid — that works as an insulator in electronics. The thicker the layer of magnesium oxide, the longer it takes for water to get through, and so the more slowly the device dissolves.

Testing their devices in a solution with a pH and temperature similar to that of the human body, Rogers’ team found that depending on the thickness of the coating, the devices worked for as little as 40 minutes or as long as five days and disappeared entirely within two weeks. That range could make the devices suitable for applications as diverse as postoperative antibacterials and extended medical monitoring. Rogers and his team have even made non-insulated devices that dissolve in just 10 to 20 seconds. “We want to engineer them for as wide a time frame as possible, from a few seconds to many years,” he says.

In one application, Rogers’ team devised a transient, flexible film to kill bacteria using electricity instead of drugs. The device’s electricity kills pathogens with heat, or thermal sterilization, a method that prevents animals from building up resistance to antibiotics. In a recent test, the device successfully killed microbes both in a petri dish and when implanted under the skin of a rat; it lasted about two weeks, the amount of time surgery patients are most at risk for post-op infections.

Second Skin

Normally, devices that monitormuscle contractions and other biological activity are too bulky to be practical anywhere but a hospital or lab. Rogers and colleagues hope to bring these applications to the street and home with a wireless circuit board that can be printed directly on skin to monitor a wide range of biological functions, including heart rate, skin temperature, muscle activity and hydration.

In an earlier version of their electronic “skin,” researchers in Rogers’ group packed temperature sensors, light detectors and other components onto a rubbery sheet that could be applied like a temporary tattoo, bending and stretching without breaking. But it washed off within a couple of days.

Their current model, less than a micron thick, dispenses with the polymer backing, instead stamping the electronics directly onto the skin and sealing the array with a spray-on bandage. The device conforms so well to the creases and troughs of human skin that it can stay on for up to two weeks before it is sloughed off. And it is so unobtrusive that people can wear it on sensitive and shifting parts of their body, like the skin of their throats.

The device could enable doctors to continuously monitor a wide range of vital functions. For example, by measuring electrical conductivity or the spread of heat in the skin, it can monitor hydration, allowing it to spot early signs of heart problems marked by water retention. It can also send small electric currents to stimulate muscles as part of a physical therapy regimen. Its noninvasiveness also makes it especially useful in neonatal care.

Recently, Rogers showed that people could control a simple computer game with a throat-mounted e-skin that sensed their voice commands by detecting muscular contractions and translating them into virtual commands such as up, down, left and right. Other volunteers could use e-skin capable of sensing muscle tensing in forearms to fly a remote-controlled helicopter.

Light Bulbs for the Brain

Neuroscientists have learned to modify animal behavior in — quite literally — a flash using optogenetics, a technique that genetically reprograms specific neurons so they respond to light. Optogenetics experiments have helped illuminate the biological bases of complex behaviors such as addiction and sleep. But the customary setup in such experiments — fiber-optic cables implanted in the brain and a heavy helmet linked to a laser — is invasive and cumbersome for mice, the usual subjects, severely hampering researchers’ ability to observe normal activity and social behavior.

To overcome these obstacles, Rogers and his lab, with colleagues at Washington University in St. Louis, developed a far less invasive light source: micro-LED devices that are easier to tote around and pose less risk to delicate brain tissue than conventional optogenetic equipment.

A central difficulty in creating the devices, Rogers says, was the inconvenient fact that making light tends to generate heat, and that neurons tolerate only a small range of temperatures. In conventional optogenetic procedures, that’s not a problem because light is beamed in via cable, keeping the actual lasers away from the brain. But Rogers wanted to nestle his tiny LEDs amid the neurons. “Operating a light bulb in the brain under the constraint that the temperature can’t go up more than half a degree [Celsius] turns out to be pretty challenging,” he says.

The dimensions of the LED devices themselves provided a solution: Each square LED is 5 microns thick and 50 microns to a side. The combination of small size and relatively large surface area allows heat to dissipate quickly enough to protect the animals’ neural tissue. Rogers and his team put four of the micro-LEDs onto a thin, flexible polymer sheet, then layered it together with sheets containing sensors to monitor temperature, light and electrical activity in a mouse brain. The resulting tongue-depressor-shaped device is only 10 microns thick, thinner than the thinnest spiderweb.

In a recent test, the team used a silk-based, water-soluble glue to attach an LED device to an ultraslender needle, then injected the needle into a targeted area in the brains of a dozen mice. Fifteen minutes later, after the glue dissolved, the team removed the needle, leaving behind only the flexible LED device — and very little tissue damage. To deliver power to the LEDs, Rogers outfitted the mice with lightweight hats equipped with a radio frequency antenna.

The slimmed-down system got results. Turning on the four micro-LEDs activated neurons in a key component of the brain’s reward circuitry, triggering the mice to prefer whichever part of the cage they were in when the light was on. “This shows we have a way to get semiconductor devices down into the brain,” Rogers says.

Just as important, he says, “We no longer have the tether.” The wireless setup permits animals to roam freely, allowing researchers to more fully study a mouse’s natural behavior — and may open the doorway, eventually, to a pragmatic form of human treatment as well.

Striving for Impact: Q & A with John Rogers

Your early work at Bell Labs in the ’90s focused on consumer products, like flexible screens with the look and feel of real paper. Why did you pivot to other areas, such as medical devices?

Many consumer electronic gadgets have limited societal benefit, and most are quickly supplanted by some next-generation thing. We’re hoping some of the things we’re pursuing can have some qualitatively different level of significance. The shift accelerated in 2002 after I gave a talk at the University of Pennsylvania, and a neuroscience student in the audience expressed an interest in putting our electronics on brains. That conversation led to a fruitful, long-lasting collaboration with his adviser and opened up clinical medicine as a focus of our research.

You went from using semiconductor materials that are inherently flexible to using silicon, a more conventional material not known for its flexibility. That feels like a step backward. Why did you do it?

I started looking for new ways to make flexible electronics out of necessity. When I was at Bell Labs, I was surrounded by amazing organic chemists who could cook up all kinds of interesting polymers and organic molecules that we could use to build transistors. When I left for Illinois, I knew I wouldn’t have my chemistry collaborators next door anymore, so I needed to find a different way to make an impact. We started to get interested in ultrathin silicon because thin geometries render any material flexible. A 2-by-4 is rigid, but a sheet of paper is not — similar materials, just different thicknesses. The same goes for silicon. A wafer is rigid and brittle, but sheets of silicon with nanoscale thicknesses are floppy and flexible.

Your devices are not only flexible, but stretchable. Why does that matter?

It makes it possible to wrap them around hemispherical shapes or soft biological tissues, like the brain or heart. For seamless, minimally invasive integration

of an abiotic system, like electronics, with a biological one, the mechanics and shapes must match up precisely. Since we can’t change biological systems to make them look like silicon chips, we’ve focused on the reverse.

How did you realize that stretchability is as important as flexibility?

Sometime in early 2005, a postdoc noticed that during the initial step of the printing process, the rubber stamps we use to print the ultrathin silicon could sometimes be slightly stretched in handling just before contact with the thin silicon. That can cause the silicon to adopt a wavy shape, almost like an accordion bellows. These shapes were formed initially by accident.

So relaxing the rubber then compressed the silicon. What effect did that have?

We were, in a sense, making the silicon do gymnastics — to buckle, stretch and deform. It took us a while to precisely understand the underlying physics of what was going on and to optimize the process, but as we’ve done so, we’ve come up with dozens of applications, including devices that conform precisely to the surfaces of body organs; or that can be attached to surgical instruments for insertion into the body with minimal harm to surrounding tissues; or that mimic nature in ways previously impossible, such as cameras that replicate mammalian-eye or insect-eye capabilities. — Jim Sullivan

[This article originally appeared in print as "Stretchy, Flexy Future."]